Behind every well-fitting garment is an unsung hero: pattern making. This crucial step in apparel production transforms fashion sketches into wearable clothing by creating the “blueprint” for each piece. Whether you’re a startup or an established brand, understanding pattern making helps you achieve better fit, reduced waste, and higher-quality garments.

At Obi-Apparel.com, we specialize in custom apparel manufacturing and sourcing, and precision pattern making is at the core of our process. In this guide, we’ll break down:

✔ What pattern making is and why it matters

✔ Traditional vs. digital pattern making

✔ How it affects fit, cost, and sustainability

✔ Why it’s critical for custom apparel

1. What Is Pattern Making? (The “Blueprint” of Fashion)

Pattern making is the process of creating 2D templates for each component of a garment (sleeves, collars, bodices, etc.). These templates guide fabric cutting and sewing, ensuring consistency across production.

Key Pattern Making Terms:

-

Sloper/Block: A basic, fitted template for a specific body type

-

Grading: Adjusting patterns for different sizes (XS–XL)

-

Draping: Creating patterns by molding fabric on a dress form

-

Notches & Seam Allowance: Marks for precise assembly

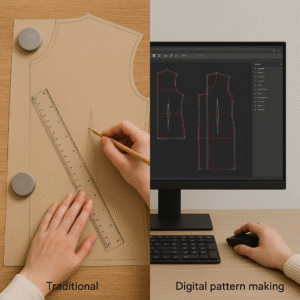

2. Traditional vs. Digital Pattern Making

| Method | Pros | Cons |

|---|---|---|

| Manual (Paper/Drafting) | Low startup cost, hands-on control | Time-consuming, hard to modify |

| Digital (CAD Software) | Faster edits, 3D previews, scalable | Requires software training |

Why Digital Wins for Modern Brands:

-

Accurate sizing (reduces returns from poor fit)

-

Easier collaboration with overseas manufacturers

-

Less material waste through optimized layouts

3. How Pattern Making Impacts Your Business

A. Fit & Quality

-

A well-made pattern prevents gapping sleeves, uneven hems, or tight armholes.

-

Brands like Everlane and Patagonia invest heavily in pattern precision to build customer trust.

B. Cost Efficiency

-

Efficient pattern layouts save up to 15% in fabric costs.

-

Fewer revisions mean faster production timelines.

C. Sustainability

-

Nesting software arranges patterns to minimize fabric waste.

-

Zero-waste pattern making (used by brands like Eileen Fisher) eliminates scraps.

4. Pattern Making for Custom Apparel

Custom clothing demands exceptional pattern making because:

✔ Each design is unique (no existing templates)

✔ Sizing varies (e.g., uniforms for diverse body types)

✔ Small batches require precision to avoid costly errors

How Obi-Apparel.com Delivers:

-

Our pattern makers use CAD software for perfect scaling.

-

We test prototypes to refine fit before bulk production.

-

Offer grading services for inclusive sizing (XXS–6XL).

5. The Future: AI & Automation in Pattern Making

Emerging tech is revolutionizing the field:

-

AI-powered pattern generation (like Vizoo or Optitex) auto-adjusts for fit.

Ready to Elevate Your Apparel with Precision Patterns?

Poor pattern making leads to ill-fitting clothes, wasted budgets, and unhappy customers. At Obi-Apparel.com, we combine traditional expertise with digital tools to craft flawless patterns for your brand.

📩 Let’s create garments that fit perfectly—contact us today!