In the fast-paced world of fashion and apparel manufacturing, quality control (QC) is not just a step in the process—it’s the backbone of brand reputation, customer satisfaction, and long-term success. At Obi-Apparel, we specialize in custom apparel manufacturing and sourcing, and we understand that delivering flawless garments is non-negotiable.

Whether you’re a startup fashion brand or an established retailer, overlooking quality control can lead to costly returns, damaged credibility, and lost customers. In this article, we’ll explore why QC matters, key stages in the process, and how partnering with the right manufacturer ensures high-quality, consistent apparel production.

Why Quality Control is Critical in Apparel Manufacturing

1. Protects Brand Reputation

A single defective product can lead to negative reviews, social media backlash, and loss of consumer trust. Implementing strict quality checks ensures your brand maintains a reputation for excellence.

2. Reduces Costs & Waste

Catching defects early—before mass production—saves money on rework, returns, and unsellable inventory. Efficient QC minimizes fabric waste, production delays, and logistical headaches.

3. Ensures Customer Satisfaction

Customers expect durable, well-fitted, and defect-free clothing. A strong QC process guarantees that every piece meets sizing, stitching, and material standards before reaching the buyer.

4. Compliance with Industry Standards

From AATCC (American Association of Textile Chemists and Colorists) to ISO certifications, adhering to quality benchmarks ensures your garments meet safety, durability, and ethical manufacturing guidelines.

Key Stages of Quality Control in Apparel Production

1. Pre-Production QC

-

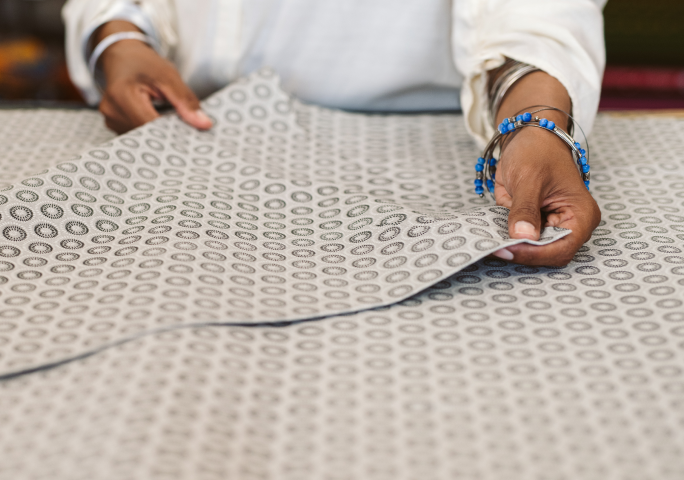

Fabric Inspection: Checking for defects like stains, holes, or color inconsistencies.

-

Pattern & Sample Approval: Ensuring sizing accuracy and fit before bulk production.

2. In-Production QC

-

Stitching & Seam Checks: Verifying seam strength, thread tension, and alignment.

-

Print & Embroidery Accuracy: Confirming logo placement, color matching, and durability.

3. Final Inspection (Pre-Shipment QC)

-

Random Sampling: AQL (Acceptable Quality Level) audits to test a percentage of finished goods.

-

Packaging & Labeling: Ensuring tags, barcodes, and packaging meet brand requirements.

How Obi-Apparel Ensures Top-Quality Garments

At Obi-Apparel, we integrate rigorous quality control at every stage of custom apparel manufacturing and sourcing. Our process includes:

✅ Third-Party Inspections – Unbiased audits for transparency.

✅ AQL 2.5 Standard – Industry-leading defect detection.

✅ Tech-Driven QC – Digital tools for precision measurements and color matching.

✅ Ethical Manufacturing – Factories audited for fair labor and sustainable practices.

By partnering with us, brands eliminate guesswork and gain a reliable, quality-focused supply chain.

Final Thoughts

Quality control isn’t just about avoiding defects—it’s about building trust, reducing costs, and scaling your brand sustainably. Whether you need custom uniforms, private-label fashion, or bulk sourcing, investing in a manufacturer with robust QC protocols is key to long-term success.

Need a partner who prioritizes quality as much as you do?

📩 Contact Obi-Apparel today for high-quality, stress-free apparel production!