In today’s world of fashion, the importance of finding high-quality, unique, and sustainable clothing has never been greater. With the increasing demand for custom apparel and personalized designs, the apparel industry in America has evolved to meet the needs of consumers who value quality, style, and ethical production practices. At Obi Apparel, we provide exceptional custom apparel manufacturing and sourcing services, helping brands and businesses create clothing that stands out in both quality and design.

In this article, we’ll dive into what makes apparel in America so special, explore the best options available, and highlight how custom apparel manufacturing can elevate your brand's presence in a competitive market.

Why Custom Apparel Manufacturing is Trending in America

America has long been known for its vast and diverse clothing market, but recently, a new trend has emerged: custom apparel. As consumers are becoming more conscious of what they wear and how it is made, there has been a shift toward personalized, custom-designed clothing. This is where companies like Obi Apparel come in, offering custom apparel manufacturing services that cater to both individuals and businesses.

Custom apparel offers several advantages:

Personalization: Consumers today are no longer satisfied with mass-produced, one-size-fits-all clothing. They want garments that reflect their style, personality, and values. Custom apparel provides the opportunity to create clothing that is truly unique.

Brand Identity: For businesses, custom apparel is an excellent way to showcase brand identity. Whether it’s a custom logo on a t-shirt, a specific design for a corporate event, or a unique clothing line for retail, custom designs allow businesses to differentiate themselves from competitors.

Sustainability: Many American consumers are increasingly concerned about the environmental impact of clothing production. Custom apparel allows for a more sustainable approach, as it often involves small-batch production, reducing waste and promoting eco-friendly materials like organic cotton and recycled polyester.

The Rise of American Apparel Brands

The American apparel market is booming, with consumers embracing both domestic and international brands that offer high-quality materials, innovative designs, and sustainable production practices. Some of the best apparel brands in America are making waves by combining craftsmanship with creativity. Let’s explore some of the key players in the industry:

Patagonia: Known for its sustainable practices and eco-friendly designs, Patagonia has long been at the forefront of environmentally conscious apparel. Their focus on recycled materials, organic cotton, and sustainable sourcing has earned them a loyal following of eco-conscious consumers.

American Eagle: A popular choice for young adults, American Eagle combines comfort and style with affordable pricing. Known for its range of casual wear, from jeans to hoodies, the brand offers a classic American style that resonates with a wide audience.

Levi’s: Synonymous with denim, Levi’s has been an American icon for decades. They continue to innovate in the denim space by introducing sustainable practices, such as waterless washing techniques and using recycled materials in their products.

Obi Apparel: As a custom apparel manufacturer, Obi Apparel specializes in providing high-quality, unique clothing options to both individuals and businesses. We offer a range of services, from sourcing apparel to full-scale custom clothing production for brands looking to make an impact.

What Makes Obi Apparel Stand Out?

At Obi Apparel, we understand that clothing is not just about looking good; it’s about feeling good too. Our commitment to custom apparel manufacturing is rooted in a desire to provide our clients with clothing that is not only stylish but also durable, comfortable, and ethically produced. Here’s what sets us apart in the American apparel market:

Custom Designs: Whether you need custom t-shirts, sweatshirts, jackets, or hats, we offer a range of products that can be customized with your brand logo, graphic designs, or artwork. Our design team works closely with you to bring your vision to life, ensuring that the end result reflects your unique brand identity.

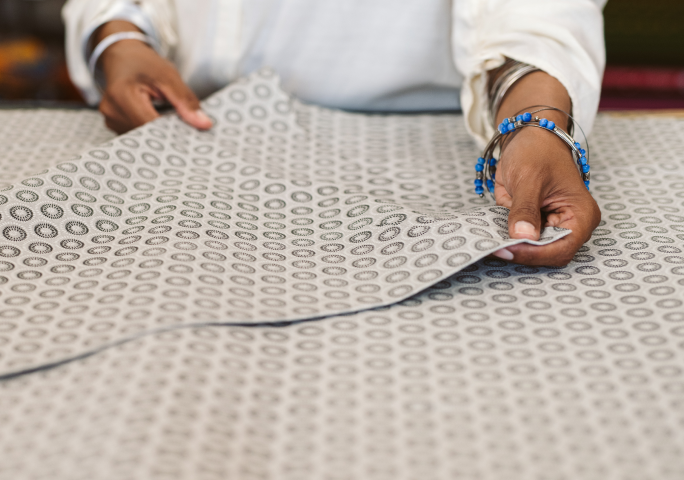

High-Quality Materials: At Obi Apparel, we prioritize high-quality materials that are both comfortable and sustainable. From organic cotton to recycled polyester, our fabrics are chosen with care to ensure that your products are both eco-friendly and built to last.

Efficient Sourcing: We work with a network of trusted suppliers and manufacturers to source the best fabrics and materials. This ensures that every piece of apparel we create meets the highest standards of quality and craftsmanship. Our global sourcing capabilities also allow us to offer competitive prices without compromising on quality.

Sustainability: We are committed to sustainable practices in every aspect of our business. From sourcing eco-friendly materials to using ethical production methods, we ensure that our custom apparel has a minimal environmental impact. This aligns with the growing demand for sustainable apparel in the U.S. and worldwide.

Why Choose Custom Apparel Manufacturing?

If you are a business owner, entrepreneur, or influencer looking to create your own line of apparel, custom manufacturing offers a variety of benefits that can help elevate your brand and stand out in a crowded market.

Unique Branding: Custom apparel is a great way to establish a strong, recognizable brand. With the right designs and consistent branding, your apparel can become a powerful marketing tool. Customers will be able to instantly identify your brand by the quality, style, and designs of your clothing.

Targeted Marketing: Custom apparel allows you to cater to specific niches and target audiences. Whether you’re designing clothing for a specific event, a particular group, or a lifestyle, custom manufacturing enables you to create exactly what your customers are looking for.

Customer Loyalty: When customers receive high-quality, well-designed clothing that speaks to their personal style or values, it builds loyalty and fosters a stronger connection to your brand. Custom apparel can lead to repeat business and word-of-mouth referrals.

Flexibility in Production: Unlike traditional retail, where you may be forced to adhere to mass production schedules, custom apparel manufacturing offers more flexibility. Whether you need small batches of apparel for a limited collection or large-scale production for a brand launch, custom manufacturing gives you the freedom to control your production timeline.

Trends in the American Apparel Industry

As the American apparel industry continues to evolve, several trends are shaping the future of fashion and custom clothing. Let’s take a look at the key trends to watch out for:

Sustainability and Eco-Friendly Clothing: Consumers are becoming more aware of the environmental impact of their purchasing decisions. As a result, sustainable materials like organic cotton, recycled fabrics, and eco-friendly dyes are gaining popularity. Brands are increasingly adopting these materials to meet consumer demand for green fashion.

Athleisure and Comfort: The rise of athleisure wear continues to dominate, with consumers seeking comfortable yet stylish clothing for both workouts and daily wear. Custom activewear, such as leggings, sports bras, and joggers, is a growing segment in the custom apparel market.

Personalization: Consumers want to express their individuality, and personalization is the key. Whether it’s custom t-shirts, embroidered hats, or personalized jackets, custom apparel allows people to wear clothing that reflects their unique personality.

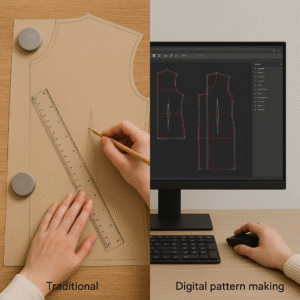

Technology Integration: The apparel industry is also embracing technology to improve design and production processes. Innovations in 3D printing and smart fabrics are paving the way for futuristic fashion solutions. Brands offering custom clothing are incorporating these technologies to provide cutting-edge designs.

How Obi Apparel Can Help You Create the Best Apparel in America

At Obi Apparel, we are dedicated to helping our clients create some of the best apparel in America by offering top-notch custom apparel manufacturing and sourcing services. Whether you’re looking to create a custom clothing line, need branded merchandise for your business, or are sourcing apparel for a special event, we have the expertise and resources to bring your vision to life.

By partnering with Obi Apparel, you’re not just getting a product; you’re getting a piece of apparel that’s been crafted with care, attention to detail, and a commitment to quality. Our services are designed to ensure that your custom apparel is not only stylish but also sustainable, durable, and reflective of your brand’s identity.

Conclusion

The American apparel market is filled with diverse options, but there’s no substitute for high-quality, custom-designed clothing that’s tailored to your brand’s unique needs. Whether you’re looking for sustainable fashion, custom activewear, or personalized clothing for your business, Obi Apparel offers the best in custom apparel manufacturing and sourcing. We ensure that every piece of apparel we create is of the highest quality, made from sustainable materials, and designed to meet the needs of today’s fashion-conscious and eco-conscious consumers.

Ready to create the best apparel in America? Contact Obi Apparel today to start designing your custom clothing line and elevate your brand!

CAD software precision (like Optitex or Gerber)

CAD software precision (like Optitex or Gerber)