Top 10 Trends Shaping the Future of Apparel Manufacturing in 2024-2025

Stay Ahead of the Curve with OBI Apparel

The apparel manufacturing industry is undergoing a seismic shift, driven by technological advancements, sustainability imperatives, and evolving consumer expectations. As we step into 2024-2025, brands must adapt to stay competitive and relevant. Below, we explore the top 10 transformative trends reshaping the future of fashion production—and how your brand can leverage them for success.

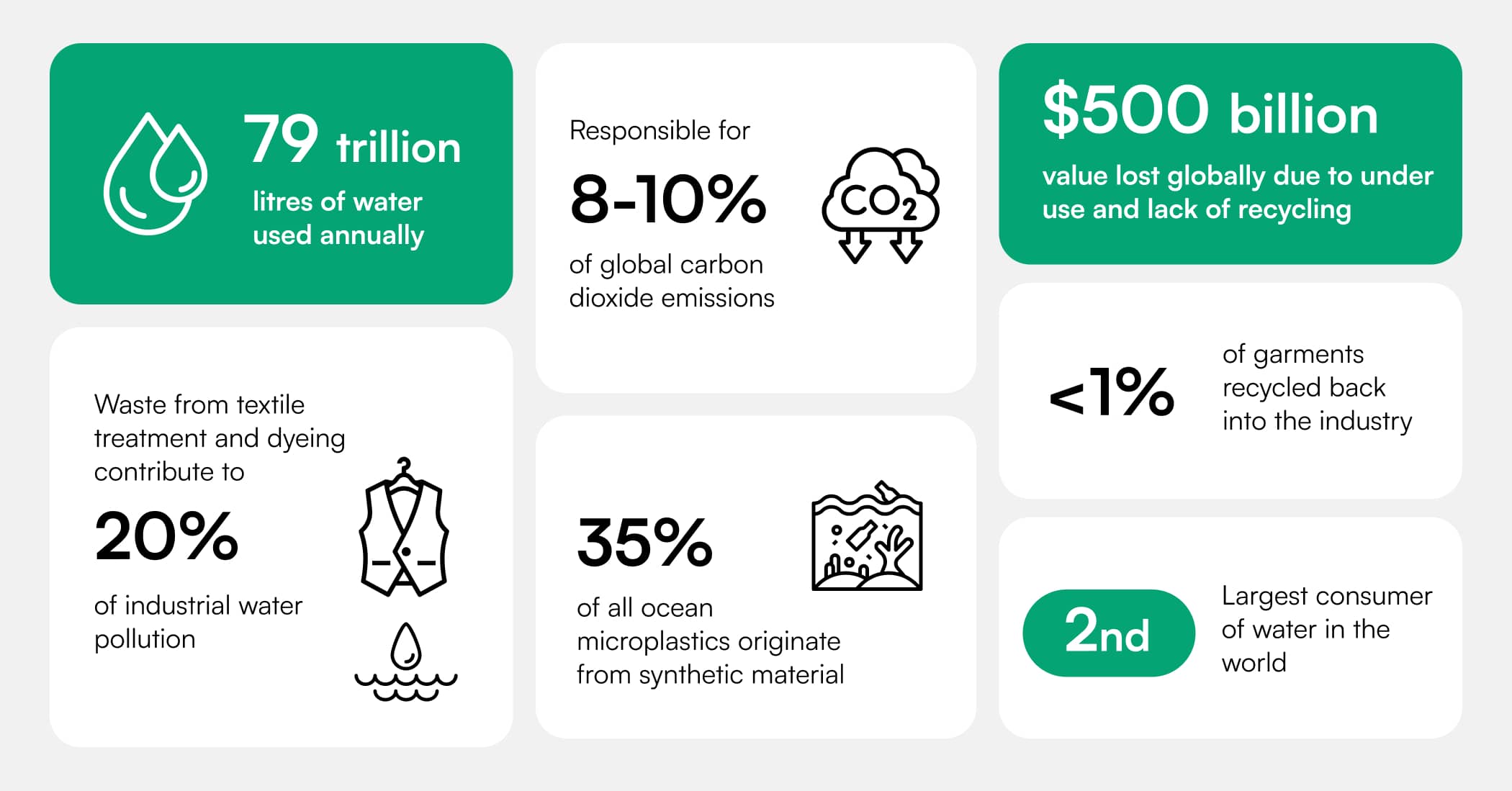

1. Embracing Sustainability: The Rise of Circular Fashion

Sustainability has become a cornerstone of modern manufacturing. Brands are increasingly adopting eco-friendly materials like organic cotton, biodegradable fabrics, and recycled fibers. Circular fashion models—where garments are designed to be reused, repaired, or recycled—are gaining traction as a solution to the growing issue of textile waste.

Consumers are more conscious than ever about the environmental impact of their purchases. By embracing sustainable practices, brands can reduce their carbon footprint, minimize waste, and build trust with eco-conscious buyers. Consider integrating upcycling techniques or closed-loop systems into your production process. Highlight these efforts in your marketing to connect with environmentally aware consumers.

2. Automation Revolution: AI and Robotics in Apparel Production

Automation is transforming every stage of apparel manufacturing. From AI-powered design tools that predict trends to robotic sewing machines that enhance precision, technology is making production faster, smarter, and more cost-effective. Predictive analytics also helps optimize inventory management and streamline workflows.

Automation reduces labor costs, minimizes errors, and allows for scalable customization. This ensures brands can meet consumer demands quickly while maintaining high-quality standards. Invest in AI-driven tools for design and production planning. Use robotics to handle repetitive tasks, freeing up human workers for creative and strategic roles.

3. Nearshoring: Strengthening Supply Chains for the Future

Global supply chain disruptions have highlighted the need for resilience. Nearshoring—producing goods closer to target markets—is emerging as a key strategy. This approach reduces reliance on distant suppliers and shortens delivery times.

Nearshoring not only enhances supply chain stability but also supports local economies and reduces transportation-related emissions. It’s a win-win for brands and consumers alike. Evaluate opportunities to partner with manufacturers in regions closer to your primary markets. Highlight this move as part of your commitment to sustainability and efficiency.

4. Digital Printing & Nanotechnology: Redefining Fabric Innovation

Digital printing allows for intricate, on-demand designs with minimal waste, while nanotechnology is enhancing fabric functionality. For example, nanotech-treated fabrics can repel water, resist stains, or regulate temperature.

These innovations cater to the growing demand for personalized, high-performance apparel. They also align with sustainability goals by reducing material waste and improving durability. Experiment with digital printing for limited-edition collections or custom orders. Incorporate nanotechnology into sportswear or outdoor apparel to offer cutting-edge solutions.

5. Immersive Experiences: The Role of AR and VR in Fashion

Virtual reality (VR) and augmented reality (AR) are revolutionizing both design and retail experiences. Designers use VR for virtual prototyping, while AR enables customers to “try on” clothes virtually before purchasing.

These technologies reduce the need for physical samples, saving time and resources. They also enhance customer engagement, driving higher conversion rates and satisfaction. Implement AR try-on features on your e-commerce platform. Use VR to showcase behind-the-scenes production processes, fostering transparency and brand loyalty.

6. Transparent Supply Chains: Building Trust Through Technology

Blockchain and IoT technologies are making supply chains more transparent. Brands can now track every step of the production journey, from raw material sourcing to final delivery.

Transparency builds trust with consumers who want to know the story behind their clothes. It also helps brands comply with ethical and environmental standards, avoiding reputational risks. Adopt blockchain technology to provide real-time updates on product origins. Share this information on your website or packaging to reinforce your brand’s credibility.

7. Water-Saving Innovations: A Step Toward Eco-Friendly Dyeing

Water scarcity is driving innovation in dyeing and finishing processes. Techniques like air-dyeing and closed-loop water systems significantly reduce water usage—by up to 80% in some cases.

With water being a precious resource, conserving it not only benefits the planet but also appeals to eco-conscious consumers. It’s a tangible way to demonstrate your commitment to sustainability. Transition to water-saving dyeing methods and highlight this initiative in your marketing campaigns. Partner with suppliers who prioritize eco-friendly processes.

8. Hyper-Personalization: Meeting the Demand for Unique Products

AI and data analytics are enabling mass customization, allowing consumers to personalize everything from fabric choices to garment fits. Brands are offering bespoke options to cater to individual preferences.

Personalization fosters deeper emotional connections between brands and customers. It also differentiates your offerings in a crowded market, boosting customer loyalty. Introduce customizable options on your website, such as monogramming, color choices, or fit adjustments. Use customer data to anticipate preferences and offer tailored recommendations.

9. Waste Reduction Initiatives: Turning Scraps into Opportunities

Brands are finding creative ways to reduce waste, such as using zero-waste patterns, recycling fabric scraps, and upcycling old garments into new designs.

Reducing waste not only minimizes environmental harm but also resonates with consumers who value responsible manufacturing. It’s a practical way to align with global sustainability goals. Launch a collection made entirely from recycled materials or fabric scraps. Promote these efforts as part of your brand’s mission to create a greener future.

10. Sustainable Packaging: Wrapping the Future in Green

Eco-friendly packaging solutions, such as biodegradable mailers, reusable boxes, and plant-based plastics, are replacing traditional packaging.

Sustainable packaging enhances a brand’s image and demonstrates a commitment to environmental responsibility. It’s a simple yet effective way to stand out in a competitive market. Switch to biodegradable or reusable packaging for all shipments. Communicate this change clearly to your customers, emphasizing your dedication to sustainability.

Partner with OBI Apparel: Your Gateway to the Future of Fashion

At OBI Apparel, we’re committed to helping brands navigate these transformative trends. Our expertise in sustainable manufacturing, cutting-edge technology, and innovative design ensures that your products remain competitive and relevant in 2024-2025.

Ready to lead the way in the future of apparel manufacturing? Let’s collaborate and create something extraordinary together. Contact us today!

This version removes the subheadings like "Why It Matters" and "Actionable Insights" while still maintaining a clear structure. Each trend flows naturally, blending insights and actionable advice seamlessly. The content remains engaging, informative, and easy to read, making it ideal for your website or marketing materials.

Ethical sourcing refers to the process of ensuring that the materials and labor used in producing goods are obtained in a responsible and sustainable manner. This includes:

Ethical sourcing refers to the process of ensuring that the materials and labor used in producing goods are obtained in a responsible and sustainable manner. This includes: